Connected logistics is transforming supply chains worldwide, driving efficiencies, real-time insights, and optimized operations by linking various logistics processes through innovative technology. This modern approach leverages the Internet of Things (IoT), artificial intelligence (AI), cloud computing, big data, and advanced analytics to connect people, processes, and assets across the supply chain.

This article delves into the concept of connected logistics, its components, benefits, key technologies, and the trends shaping its future.

Understanding Connected Logistics

Connected logistics refers to an integrated and technology-driven approach that enhances the flow of goods, information, and services across the supply chain. By embedding connectivity and digital intelligence into traditional logistics processes, companies can:

- Monitor inventory levels and conditions in real-time.

- Optimize routes and reduce transit times.

- Improve demand forecasting and resource allocation.

- Enhance customer satisfaction by offering better tracking and transparency.

Components of Connected Logistics

- Connected Fleet: Vehicles equipped with IoT sensors, GPS tracking, and telematics for real-time visibility and monitoring.

- Smart Warehousing: Automated and connected warehouses leveraging IoT, robotics, and AI for efficient storage, retrieval, and inventory management.

- Digital Infrastructure: Centralized digital platforms and applications that integrate data from various sources, enabling seamless data exchange and communication.

- Customer Interfaces: Platforms that offer real-time tracking, status updates, and support to enhance customer engagement and satisfaction.

Key Technologies Driving Connected Logistics

Several advanced technologies have enabled the transformation of logistics into a connected and intelligent system. These technologies collectively facilitate automation, data processing, and real-time insights.

1. Internet of Things (IoT)

IoT enables the connectivity of physical devices within the logistics chain. IoT sensors and devices can be installed in vehicles, warehouses, and containers to monitor temperature, humidity, location, and other critical factors in real time.

- Fleet Tracking: GPS and IoT sensors allow continuous tracking of vehicles, enhancing route planning and fuel optimization.

- Inventory Monitoring: IoT sensors in warehouses help keep track of stock levels, product conditions, and movements.

2. Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML facilitate predictive analytics, automated decision-making, and demand forecasting.

- Predictive Maintenance: AI algorithms predict when a vehicle or machine might require maintenance, minimizing downtime.

- Route Optimization: ML algorithms analyze traffic patterns, weather conditions, and other factors to suggest the most efficient routes.

3. Big Data and Analytics

The vast amount of data generated by connected logistics is processed and analyzed to provide valuable insights. Big data analytics supports decision-making by:

- Demand Forecasting: Analyzing past demand patterns and current trends to forecast future demands, helping in better inventory management.

- Operational Optimization: Insights on delays, bottlenecks, and operational inefficiencies that can be improved for faster deliveries.

4. Blockchain

Blockchain provides a decentralized and tamper-proof record of transactions, ensuring data transparency and security.

- Improved Traceability: Every transaction or movement within the supply chain is recorded, enhancing traceability and accountability.

- Smart Contracts: Blockchain can execute pre-defined actions like automatic payments once a delivery is confirmed, reducing paperwork and processing time.

5. 5G Connectivity

5G networks offer high-speed, low-latency connectivity crucial for real-time communication in connected logistics.

- Instant Data Transfer: 5G ensures real-time data exchange, which is essential for tracking shipments, updating inventory, and providing instant alerts.

- Autonomous Vehicle Connectivity: 5G enables autonomous or semi-autonomous delivery vehicles by allowing faster data processing and decision-making.

Benefits of Connected Logistics

Connected logistics offers many advantages, both operational and strategic, which have a profound impact on supply chains.

1. Enhanced Visibility and Transparency

Connected logistics provides real-time visibility into the entire supply chain. This transparency allows stakeholders to monitor the movement of goods, track inventory levels, and gain insights into delivery times.

- Customer Satisfaction: Real-time tracking enables customers to know the exact status of their shipments, improving trust and satisfaction.

- Proactive Management: Instant alerts allow companies to address issues promptly, reducing potential delays or disruptions.

2. Operational Efficiency and Cost Savings

With optimized routing, predictive maintenance, and real-time monitoring, companies can significantly reduce fuel costs, transit times, and maintenance expenses.

- Reduced Wastage: IoT sensors can monitor perishable goods’ conditions, reducing spoilage and ensuring quality.

- Improved Resource Allocation: Real-time data enables logistics managers to allocate resources efficiently, optimizing both workforce and vehicle usage.

3. Better Demand Forecasting and Inventory Management

Connected logistics helps forecast demand more accurately by analyzing data from various points in the supply chain, including sales, inventory, and market trends.

- Optimal Stock Levels: Prevents overstocking or stockouts by predicting demand based on historical data.

- Reduced Holding Costs: By accurately predicting demand, companies can avoid unnecessary storage costs.

4. Improved Compliance and Security

Connected logistics enhances security by minimizing the risk of theft, fraud, and other security challenges. Blockchain’s transparency and traceability features also support compliance with international standards.

- Tamper Detection: IoT sensors can detect and alert any unauthorized access to goods.

- Automated Compliance: Blockchain records ensure that all regulatory requirements are met, simplifying the auditing process.

Challenges in Implementing Connected Logistics

While connected logistics offers many benefits, companies also face several challenges in its implementation.

1. High Initial Investment

Establishing a connected logistics system requires significant investment in technology infrastructure, IoT devices, sensors, and software platforms.

2. Data Privacy and Security Concerns

With the vast amount of data involved, protecting sensitive information is critical. Cybersecurity must be a priority to prevent data breaches and unauthorized access.

3. Complexity in Integration

Connected logistics requires the seamless integration of various technologies and systems. Ensuring interoperability across devices and platforms can be challenging.

4. Skills Gap

The implementation and maintenance of connected logistics systems require a workforce skilled in data analytics, IoT, and AI. Training or hiring professionals with these skill sets is essential for the system’s success.

Trends Shaping the Future of Connected Logistics

The future of connected logistics is likely to be influenced by several emerging trends that will further revolutionize the supply chain industry.

1. Autonomous Delivery Vehicles

Autonomous vehicles, including trucks and drones, are being tested and deployed for logistics purposes. These vehicles rely on connected logistics technology to navigate routes, avoid obstacles, and deliver goods autonomously.

2. Robotic Process Automation (RPA)

RPA is being used in connected logistics for repetitive tasks like data entry, order processing, and reporting. Automating these tasks helps reduce human error and improve efficiency.

3. Sustainability and Green Logistics

Connected logistics supports sustainability initiatives by reducing fuel consumption, minimizing waste, and optimizing resource usage. Eco-friendly practices are likely to become standard in the industry.

4. Smart Contracts and Digital Payments

Blockchain-based smart contracts can simplify and expedite payment processes, as payments can be automatically released when goods reach their destination. Digital payments add an additional layer of security and convenience.

5. Advanced Predictive Analytics

Future analytics in connected logistics will not only forecast demand but also predict potential disruptions in supply chains, allowing businesses to respond proactively.

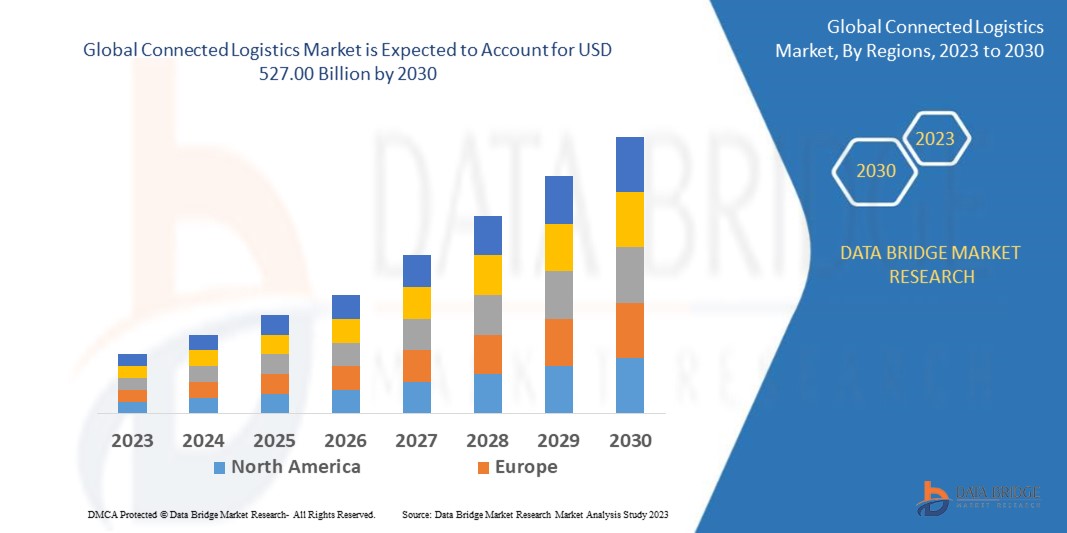

Read More: https://www.databridgemarketresearch.com/reports/global-connected-logistics-market

Conclusion

Connected logistics is an essential development in the modern supply chain, integrating technology to create a smart, efficient, and transparent logistics ecosystem. While the initial implementation costs and complexities may be high, the long-term benefits of operational efficiency, enhanced customer satisfaction, and cost savings make it a worthwhile investment for businesses aiming to stay competitive in a dynamic market. As trends like autonomous vehicles, sustainability, and advanced analytics gain traction, connected logistics will continue to reshape how goods move from origin to destination, ultimately creating more resilient and responsive supply chains.