Folders can be assembled to create reusable custom sleeve boxes at home easily. It is a crucial skill for every person who wants to add value to their small business or anyone who is a crafter and wants to package their gift more specially. By using a few tools and materials you can easily create sleeve boxes that not only provide perfect protection for the items but also contribute to making your brand impressive. In this article I will be taking you through various ways of building these portable boxes by showing you steps that anyone can follow.

Understanding Sleeve Boxes

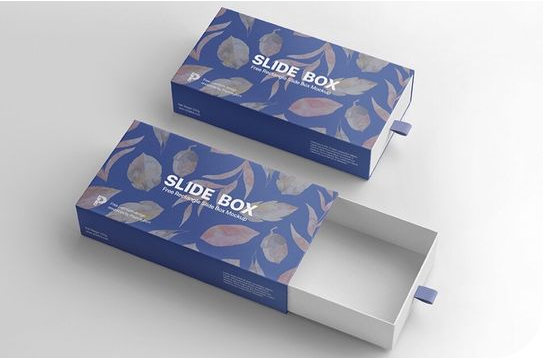

Custom sleeve boxes are normally used in packaging because of their appeal and appropriateness for packaging. These boxes contain a tray that fits into a sleeve in a much more aesthetically convincing manner for displaying goods. Custom sleeve boxes with logos can be made in different sizes and styles, so the box will fit the item perfectly. They also provide the branding opportunities that are essential for any business that wishes to popularize their logo and design. If you are now ready to begin learning how to create sleeve packaging, it is important to get to know the basics first.

Gathering Your Materials

These guidelines provided below can help build custom sleeve boxes at home, with the right tools and materials. To make the box, you will require cardboard/paper board sheets, a ruler, a pencil, scissors, and a glue stick or double-sided tape. If you wish to brand the sleeve, it would be advisable to have some specially printed sleeve boxes made or print your graphics at home. Make sure you have a clean area to work and assemble all the parts as the absence of clutter will facilitate the assembly process.

Marking and Cutting the Cardboard

Evaluations are very significant in the construction of sleeve boxes to allow for the creation of unique boxes. First, consider the size of the product for which you are going to use the packaging material. Place a ruler on the cardboard sheets and trace around it to achieve the desired measurements with an allowance that will help it fit perfectly when placed on the stuffed toys. Cautiously employ scissors or a craft knife to cut out the marked sections, taking care to produce clean straight lines for the process of assembling. This step is crucial as it enables the production of neat sleeve boxes that will dazzle your clients.

Scoring and Folding

After you have done that, then it will be necessary to score and fold the cardboard. When marking the pieces to fold, it is necessary to use a ruler and score with something that is not sharp like a bone folder or the back of the knife. This will make the folding process easier and cleaner. It is very important that the folding of clothes has to be done neatly so that it can easily fit in bags and hangings for storage. Accomplish the folding of the scored lines that will result in the creation of the tray and sleeve. It is advisable to spend a few minutes at this stage to ensure that the folds are neat and that the box looks good when you are done.

Assembling the Tray and Sleeve

You now have the tray and sleeve components of this product so it is now high time that you join them together. Begin by placing the tray and with glue or double-sided tape, apply it at the sides of the patch. To make the tray, lift the sides and join the edges so they lock into place. Perform the same for the sleeve until both elements are strong and well-positioned with each other. While custom sleeve boxes wholesale may contain ready-made pre-cut sizes, it is fun to cut the sleeves by oneself occasionally.

Adding Branding with Custom Prints

The use of a custom sleeve is a measure of branding your custom sleeve boxes, and this is essential in the process of making the right impression. If you choose custom-printed sleeve boxes, make sure that the printed images correspond to the assembled sleeve boxes. It is also possible for you to decorate them with some labels or stickers that contain your logo to increase the canopy logo imprint. In case of a DIY look at using printable designs that can easily be printed at home to avoid the need for printing services. This not only makes the packaging unique and individual but also strengthens your brand image.

Conclusion and Quality Assurance

Once you have put together your sleeve box packaging alongside their respective brand labels, the next course of action is to carry out quality assurance. Open the box and check whether the edges are glued well and whether the dimensions are accurate. Additional stations can also be incorporated into the product packaging by tying a decorative ribbon or even incorporating a stamp to enhance the appearance of the packaging. In the process of practicing place utility, paying attention to higher quality will not only help in the beautification of the products but will also get an appreciation from customers due to the level of professionalism.

Conclusion

Making custom sleeve boxes at home is not a complicated process but a fun activity that can also improve the packaging techniques. With the help of these simple instructions, you can make elegant and practical boxes that will reflect the image of your company. In conclusion, undertaking custom mug boxes wholesale or even creating your packaging is worth the effort as it all goes a long way in making customers happy and creating brand loyalty. By doing so, your competition’s custom sleeve boxes will not be in a similar category with the other common boxes in the market.