In today’s rapidly evolving industrial landscape, artificial intelligence (AI) and machine learning (ML) are transforming manufacturing IT services in unprecedented ways. With a primary focus on enhancing productivity, minimizing costs, and optimizing processes, these technologies are reshaping how manufacturers operate. As a part of this transformation, digital twin in manufacturing is emerging as a pivotal concept, offering real-time simulations and predictive insights that can improve operational efficiency and decision-making.

This article explores the growing influence of AI and ML in manufacturing IT services and how they support the adoption of digital twins, driving the industry toward a more automated, efficient, and responsive future.

1. The Role of AI and Machine Learning in Manufacturing IT Services

Manufacturing IT services have long been at the forefront of implementing technologies that optimize production and maintenance. With the integration of AI and ML, the potential for growth in this sector has expanded significantly. Here’s how these technologies are making an impact:

- Enhanced Data Analysis: AI and ML can process large volumes of data from production equipment, quality control systems, and supply chains, extracting valuable insights. This helps manufacturers identify patterns, anomalies, and opportunities for improvement that may not be evident through traditional analysis methods.

- Predictive Maintenance: One of the standout applications of AI in manufacturing IT services is predictive maintenance. By analyzing data from sensors embedded in machinery, AI algorithms can predict equipment failures before they happen, reducing downtime and maintenance costs.

- Quality Control: AI-powered systems are revolutionizing quality control by detecting defects in real-time. Machine learning models can be trained on large datasets of images or measurements to identify deviations, enabling faster responses and reducing waste.

These AI-driven advancements not only streamline operations but also enable manufacturers to respond more swiftly to changes in demand or operational challenges.

2. AI-Powered Automation in Manufacturing Processes

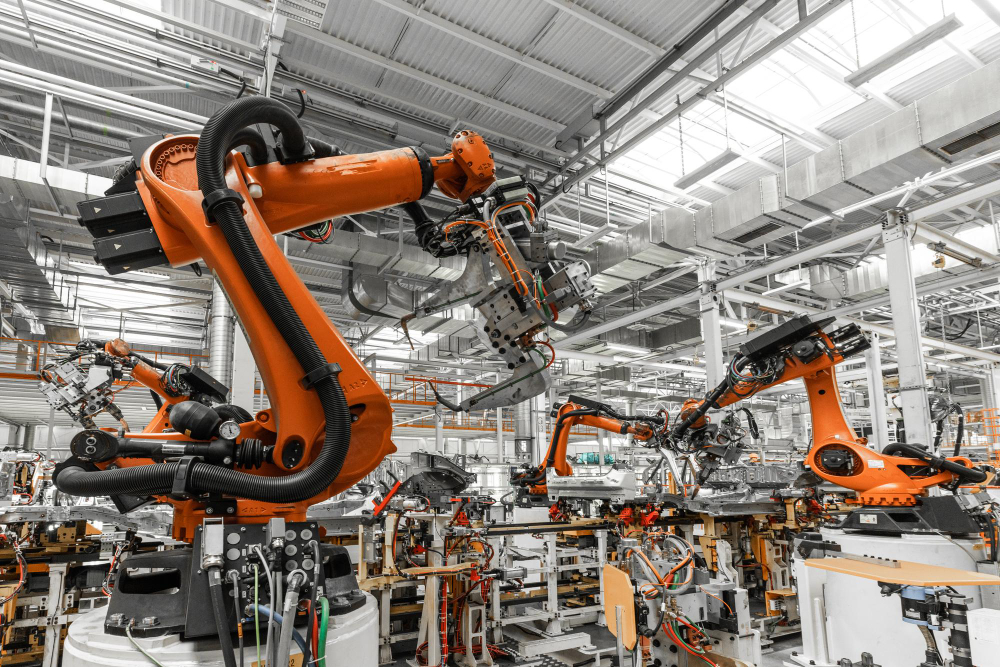

Automation has always been an essential component of manufacturing, but with AI, it has reached new heights of sophistication and adaptability. AI-based automation allows systems to adjust processes autonomously based on real-time data.

- Robotic Process Automation (RPA): RPA, powered by AI, enables robots and automated systems to handle repetitive tasks with minimal human intervention. In manufacturing, this includes assembling parts, packaging products, and handling materials, which increases efficiency and consistency.

- Cognitive Automation: Unlike traditional automation, which follows a pre-set sequence, cognitive automation uses AI to adapt and make decisions. For example, an AI system can alter production parameters if it detects that a material or component quality is below the required standard, ensuring consistent output quality.

AI-powered automation not only improves operational efficiency but also frees up human workers to focus on tasks requiring creativity, problem-solving, and supervision.

3. Digital Twin in Manufacturing: Transforming Production and Maintenance

The concept of a digital twin—a virtual replica of a physical asset or system—has gained traction in manufacturing, where it serves as a bridge between the physical and digital realms. Through the integration of AI and ML, digital twins can replicate, simulate, and predict the performance of manufacturing assets in real-time.

- Enhanced Monitoring: A digital twin monitors the physical environment through data collected by sensors, which is then used to create a real-time virtual representation. This allows manufacturers to monitor the condition of machinery, production lines, and even entire facilities, optimizing performance.

- Predictive Capabilities: AI and ML models used with digital twins provide predictive capabilities. By analyzing data from the twin, manufacturers can forecast potential issues, predict maintenance needs, and avoid costly downtime.

- Process Optimization: Digital twins can simulate process changes before they are implemented in the physical world. For instance, altering the speed of a conveyor belt, changing a manufacturing sequence, or adjusting machine settings can all be tested digitally, ensuring the best results without risking disruptions to actual production.

The application of digital twin in manufacturing is a key example of how AI and ML are enhancing IT services, allowing manufacturers to make data-driven decisions, reduce risks, and optimize workflows.

4. AI-Driven Supply Chain Management

Supply chain management in manufacturing is another area where AI and ML are making transformative impacts. From inventory management to logistics, these technologies enhance visibility and responsiveness across the supply chain.

- Inventory Optimization: AI algorithms analyze demand trends and lead times, helping manufacturers maintain optimal inventory levels. This reduces the risk of overstocking or stockouts, keeping production schedules on track.

- Supplier Relationship Management: By analyzing supplier data, AI can predict supplier performance, helping manufacturers make informed decisions about sourcing and procurement. This ensures a reliable supply chain that adapts to changes in demand or market conditions.

- Logistics and Distribution: AI-powered systems can optimize logistics by analyzing data from transport networks and predicting potential delays. This helps manufacturers deliver products more reliably, improving customer satisfaction and reducing costs.

AI-enhanced supply chain management improves efficiency, resilience, and customer satisfaction, making it a valuable addition to manufacturing IT services.

5. Customization and Personalization in Production

With AI and ML, manufacturers can now offer more personalized products without sacrificing efficiency. This approach, often referred to as “mass customization,” involves using AI to adapt manufacturing processes to meet individual customer requirements.

- Flexible Manufacturing Systems (FMS): AI-powered FMS allow manufacturers to switch production lines quickly to accommodate custom orders, minimizing downtime.

- Smart Product Configurators: AI-driven configurators enable customers to customize products, from choosing materials to selecting features. The configurator then communicates with manufacturing systems to produce the personalized item.

- Adaptive Quality Control: AI-based quality control systems can adjust criteria based on the specific requirements of a customized product, ensuring high-quality output regardless of customization.

Customization driven by AI helps manufacturers stay competitive in a market that increasingly values personalization while keeping production costs under control.

6. The Impact of AI on Workforce Management

AI is not only transforming the technical aspects of manufacturing but also revolutionizing workforce management. By streamlining workforce allocation, training, and performance management, AI in manufacturing IT services helps optimize human resources.

- Smart Scheduling: AI algorithms can analyze production schedules and workforce availability to allocate the right number of workers to each shift, reducing labor costs and enhancing productivity.

- Skill Development and Training: AI-powered training programs personalize learning paths for employees based on their skills and experience. For example, VR simulations powered by AI can provide realistic training scenarios, preparing workers for various manufacturing tasks.

- Safety and Compliance: AI-based systems monitor workplace conditions and ensure compliance with safety standards. By analyzing data from sensors and cameras, AI can detect unsafe conditions and alert managers, preventing accidents.

Through AI-driven workforce management, manufacturing IT services can improve productivity, safety, and employee satisfaction, addressing the industry’s workforce challenges.

7. Challenges and Considerations in Implementing AI and Machine Learning

Despite the benefits, there are challenges associated with implementing AI and ML in manufacturing IT services. Some of these challenges include:

- Data Privacy and Security: As AI relies on vast amounts of data, maintaining data privacy and cybersecurity becomes critical. Manufacturers must safeguard their data against cyber threats and ensure compliance with data protection regulations.

- Cost of Implementation: Deploying AI and ML solutions can be costly, especially for small and medium-sized manufacturers. While these technologies can deliver long-term cost savings, the initial investment may be a barrier for some.

- Skills Gap: Implementing AI and ML requires a skilled workforce familiar with data science, machine learning, and IT infrastructure. Bridging the skills gap is essential to fully leverage the potential of these technologies.

Addressing these challenges requires careful planning, investment in workforce development, and collaboration with technology providers to ensure a smooth transition.

8. Future Prospects of AI and Machine Learning in Manufacturing IT Services

The future of AI and ML in manufacturing IT services is promising, with ongoing advancements making these technologies more accessible and powerful. Emerging trends include:

- Integration with IoT and Edge Computing: Combining AI with IoT and edge computing allows manufacturers to process data closer to the source, enabling real-time decision-making and reducing latency.

- Increased Adoption of Autonomous Systems: AI-powered autonomous systems, such as automated guided vehicles (AGVs) and robots, are expected to become more common, handling complex tasks with minimal human intervention.

- Greater Use of Digital Twins: The concept of digital twins will continue to evolve, providing more detailed and accurate simulations that help manufacturers optimize operations and reduce risks.

As these trends evolve, the role of AI and ML in manufacturing IT services will expand, driving the industry toward a more innovative, efficient, and agile future.

Conclusion

AI and machine learning are revolutionizing manufacturing IT services, offering solutions that optimize processes, reduce costs, and improve quality across the board. With technologies like digital twin in manufacturing, manufacturers gain a powerful tool for real-time monitoring, predictive maintenance, and process optimization. Despite challenges in implementation, the benefits of AI and ML are undeniable, paving the way for a future where manufacturing is more automated, data-driven, and resilient.

The rise of AI in manufacturing is not just a trend; it’s a transformative shift that is shaping the industry’s future. By adopting AI-driven solutions, manufacturers can stay competitive in a global market that demands efficiency, customization, and adaptability.